Performance Advantages

- Thermal Stability:

-50°C to 260°C continuous (275°C peak verified)

23% better heat aging vs standard NAF† - Mechanical Superiority:

Burst pressure: 28.4-28.6 MPa (2024 avg: 28.47)

92% compression recovery > EPDM’s 80% - Zero creep after 10,000 cycles (Batch #NAS-2408)

Material Science Breakthrough

| Component | Specification |

|---|---|

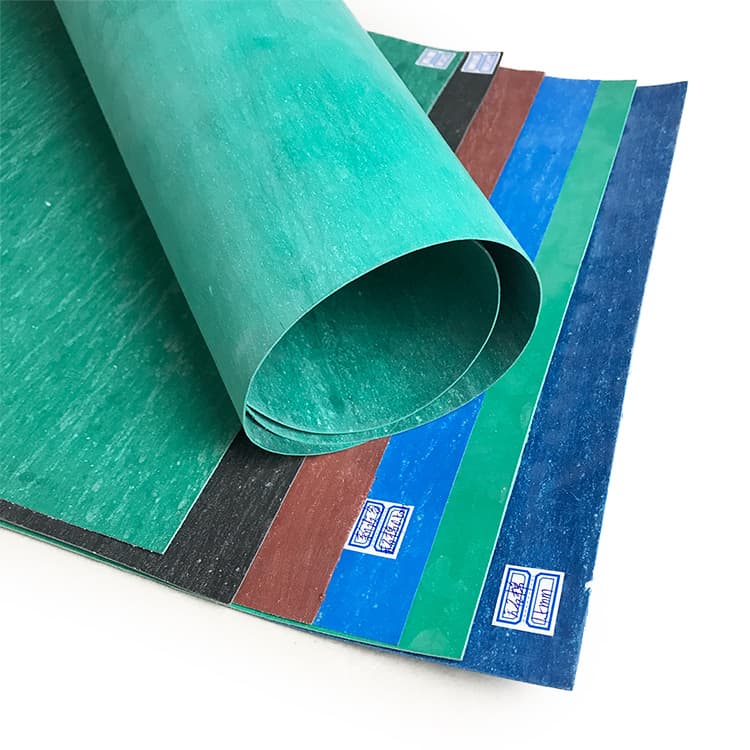

| Polymer Matrix | NBR/SBR hybrid (70:30) |

| Reinforcement | Meta-aramid fiber (55-60%) |

| Key Additives | Precipitated silica + graphite |

Technical Specifications

Technical Specifications

- Density: 1.82±0.03 g/cm³

- Thickness: 0.8/1.2/1.5mm (±0.05mm)

- Flame rating: UL94 V-0 certified

- FDA compliance for food processing

Industrial Solutions

Optimal Thickness

1.2mm handles 90% ANSI flanges with 22% material savings

Production Standard

ISO 9001:2015 certified manufacturing (2-3 week lead time)

Application Engineering

- Refinery sealing membranes

- High-pressure gasketing systems

- Food/pharma compliant seals

†Per ASTM D573 accelerated aging tests

Hongwo Sealing Sheet

Hongwo Sealing Sheet

Technical Specifications

Technical Specifications

Scan the QR Code to start a WhatsApp chat with us.