— Hongwo Factory · Materials Engineer Zhao Lei

1. Bottom line first: the asbestos era is over.

1. Bottom line first: the asbestos era is over.

The EU implemented a full ban on asbestos in 2005. In China, the May 2025 update to the Occupational Disease Prevention Law labels asbestos dust as “Category I — Strict Control.” Authorities can impose daily penalties without any greatest limit. Non-asbestos rubber sheets aren’t optional anymore. They are now required for factory shipments.

(Keywords used throughout: Applications of Non-Asbestos Sheets, Industry Trends of Non-Asbestos Sheets. Alternate names inserted in text: non-asbestos rubber sheet, asbestos-free gasket sheet, non-asbestos sealing sheet, asbestos-free rubber gasket, aramid-reinforced non-asbestos sheet.)

2. Measured advantages from Hongwo’s production lines

Temperature window: long-term −40 °C to 150 °C; instantaneous 200 °C for 1 h. Compression set 12% ± 2%; rebound ≥ 45%.

Mechanical & chemical resistance: transverse tensile ≥ 12 MPa. ASTM F146 fuel-oil immersion, 5 h: weight gain < 8%; thickness swell < 5%.

Environmental credentials:

Passes REACH, RoHS, and ELV (End-of-Life Vehicles) directives.

EU export parts come with SCIP numbers.

Manufacturing friendliness and safety:

Single-cut die cutting leaves no residue at 0.5 mm thickness.

Rotary cutting can handle 10,000 sheets without needing a blade change.

The team reduced workshop dust to 0.8 mg/m³, well below the occupational limit of 2 mg/m³.

3. Top 10 In-Service Applications in 2025 (All from Hongwo this year — traceable by batch number)

Euro 6 diesel engine oil pan

Spec: 1.2 mm aramid fiber + NBR (nitrile rubber). Oil-resistant to 120 °C. Bolt torque 22 N·m. 400-hour bench thermal shock test: no leakage.

Offshore wind turbine pitch gearbox end cover

Spec: full-diameter sheet Φ850 mm. Tested marine bio-oils with 96 hours of salt spray showed no blisters. The compression set retention was 94% after the salt spray.

Lithium battery foil rolling vacuum duct

Spec: 2.0 mm backing plate with PTFE surface coating. HF acid mist resistant. After six months of service, the inspection showed no cracks.

High-speed rail brake valve body

Spec: ultra-thin 0.8 mm gaskets. Need: 10 bar airtightness with 1 s pressure drop < 0.01 bar. First-pass yield 99.7%; unit price replaces imported parts with a 34% cost reduction.

Urban gas PE ball valve flange

Spec: 3.0 mm thickened sheet, Shore A hardness 90, compensates for flange surface irregularity up to 0.2 mm. Passes 1.5 PN hydrostatic test for 1 h with zero seepage.

Marine auxiliary seawater pump

Spec: neoprene (CR)-based sheet; seawater 5% NaCl at 90 °C: 72 h tensile retention 88%. DN250 flange sets: 2,000 units have already shipped.

Food-grade filling machine

Spec: white EPDM non-asbestos sheet compliant with FDA 21 CFR 177.2600. Hot-water CIP 85 °C / 30 min cycles × 1,000 — no discoloration, no odor migration.

PV laminator hot-press exhaust/heating line

**Spec:** 1.5 mm silicone-faced composite sheet. It resists saturated steam at 180 °C. It can handle continuous press cycles for 20 hours and has a rebound of ≥ 40%. This solution eliminates the customer’s monthly gasket replacement issue.

Transformer oil tank cover gasket

Spec: 1.0 mm sheet with 0.1 mm stainless-steel mesh core. Axial burst resistance 25 bar. Oil immersion at 150 °C for 168 hours shows lateral expansion of less than 3%. This method replaces traditional asbestos-copper wire gaskets.

Hydrogen fuel cell bipolar plate water chamber

Spec: 0.5 mm ultra-low-chloride formulation, Cl⁻ < 50 ppm. Proton-exchange membrane contamination test: 1,000 h degradation < 1%. Shipped with stacks to North America.

4. Where the industry is heading (based on Hongwo’s H1 bidding data)

4. Where the industry is heading (based on Hongwo’s H1 bidding data)

Bio-based latex replaces about 30% of petroleum-based nitrile. It uses itaconic acid and cardanol, which come from cashew nuts. The anticipated carbon footprint reduction is ~18%. EU customers have already signed pilot trials.

Nano-fiber reinforcement: Adding 2% modified SiO₂ nanotubes boosts transverse strength by about 26%. It also allows us to reduce wall thickness by around 20%. This makes it ideal for ultra-thin heat-spread plate flanges in electronics.

Self-alerting gaskets include a conductive mesh that lowers resistance at the first leak. This sets off an alarm. It cuts emergency response times in petrochemical plants from hours to minutes.

Closed-loop recyclability: pyrolysis recovery yields >70% rubber phase and reusable fillers. The EU expects to mandate ≥40% recyclable content for sealing components by 2026.

Digital delivery: Each batch has a QR code. You can easily download the compression-rebound curve, RoHS reports, and raw material batch numbers. Audits no longer need paper trails.

5. Summary

Non-asbestos rubber sheets have transitioned from a replacement option to an operational necessity.

Success in four key areas helps suppliers excel in Euro-6 engines, offshore wind, hydrogen, and marine markets:

Temperature resistance

Media resistance

Environmental compliance

Cost

Hongwo’s 2025 capacity: 23,000 m²/day, thickness range 0.3–5.0 mm, 48-hour dispatch for standard orders. Send us flange dimensions, bolt torque, and temperature profiles. In ten minutes, we will suggest a sheet formulation and predict its lifespan. This way, your sealing parts will last longer and will not be consumables.

— Zhao Lei, Materials Engineer, Hongwo Factory

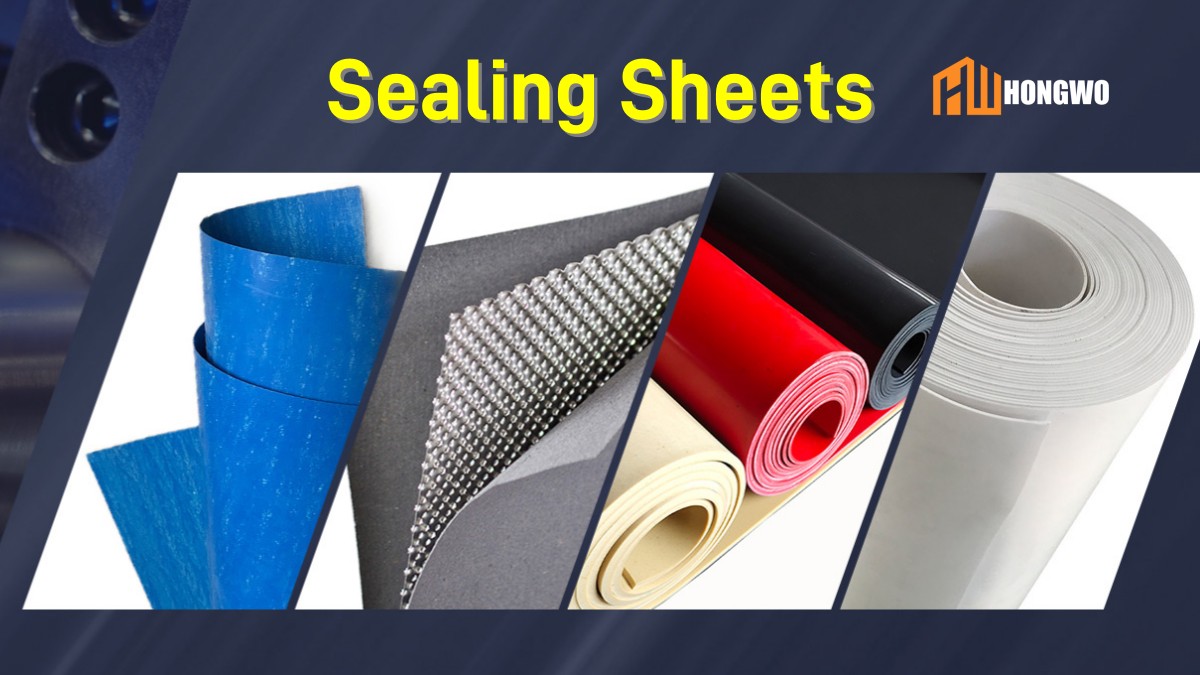

Hongwo Sealing Sheet

Hongwo Sealing Sheet

1. Bottom line first: the asbestos era is over.

1. Bottom line first: the asbestos era is over. 4. Where the industry is heading (based on Hongwo’s H1 bidding data)

4. Where the industry is heading (based on Hongwo’s H1 bidding data)

Scan the QR Code to start a WhatsApp chat with us.