1. Material Overview

1. Material Overview

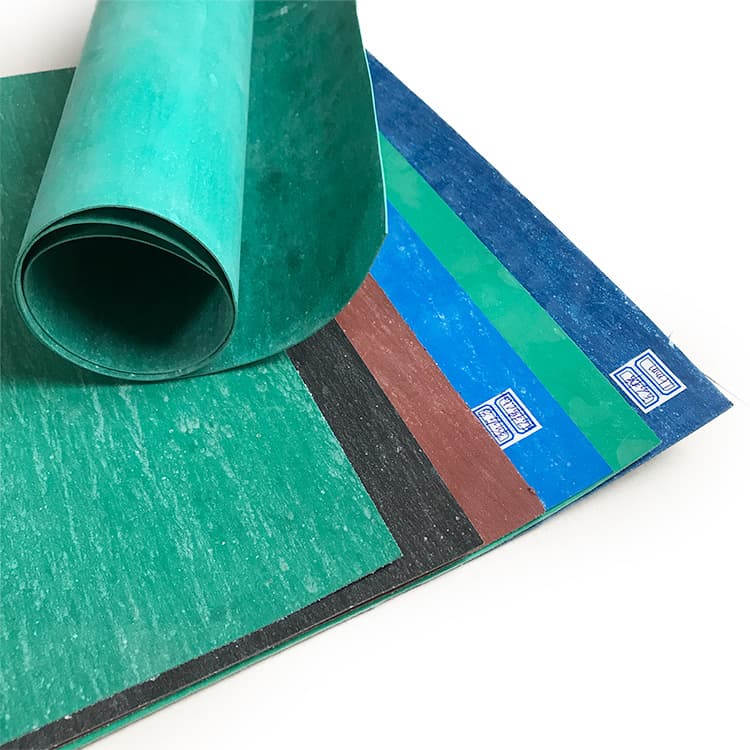

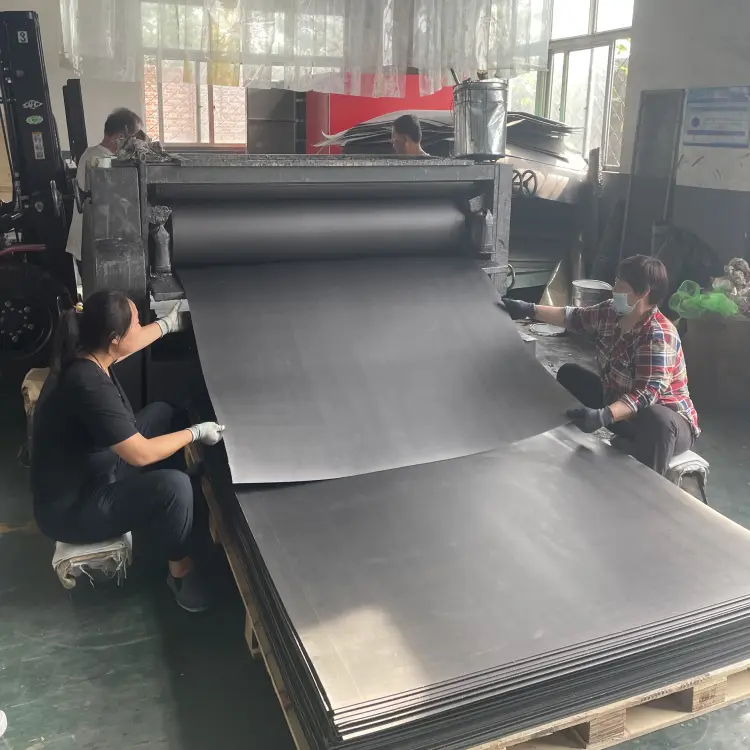

Asbestos Rubber Sheet, also known as Compressed Asbestos Fiber (CAF) Rubber Sheet, is a plate-type sealing material. It is produced by reinforcing chrysotile or crocidolite asbestos fibers as a structural skeleton, mixed with rubbers such as NBR, NR, or EPDM and inorganic fillers, followed by hot calendaring and vulcanization.

According to GB/T 3985 and ASTM F104 standards, asbestos rubber sheets are classified by temperature and pressure resistance into low-pressure (XB200), medium-pressure (XB350), and high-pressure (XB450) grades. By media adaptability, derivative types include oil-resistant, acid/alkali-resistant, and high-temperature-resistant grades.

2. Typical Application Cases

Steam Turbine Main Valve Flange in Thermal Power Plants

A Huaneng 660 MW supercritical unit operates at 24.8 MPa and 566 °C. The original graphite spiral wound gasket suffered from stress relaxation leakage during frequent start-stop operations. After replacing it with a high-pressure asbestos rubber sheet (XB450, 3 mm) combined with a 0Cr18Ni9 stainless steel inner ring, post-operation inspections after two years showed 22% compression retention, no delamination, and no permeation. Annual downtime loss was reduced by approximately RMB 1.4 million per unit.

Heat Exchanger Manhole in Petrochemical Units

In Sinopec Maoming’s reforming unit, the E-201 heat exchanger operates at 3.2 MPa and 450 °C with oil-gas media. Earlier PTFE gaskets suffered torque loss due to creep under high temperature. Switching to NBR-modified oil-resistant asbestos rubber sheet extended overhaul intervals from 6 months to 18 months, saving ~RMB 350,000 per cycle.

Wet Chlorine Pipelines in Chlor-Alkali Industry

In a Xinjiang chlor-alkali plant, wet chlorine gas pipelines (0.6 MPa, ambient temperature, with saturated chlorine water and HCl mist) adopted blue asbestos + FKM composite acid/alkali-resistant asbestos rubber sheets. After five years, no embrittlement or flange corrosion was observed, achieving 2.5 times longer service life than EPDM gaskets.

Hot Blast Pipework in Metallurgy

Baosteel’s No. 4 blast furnace hot blast pipe operates at 220 °C, 0.45 MPa, with cyclic thermal shocks. Using XB350 asbestos rubber sheet (4 mm) + graphite coating, the material compensated flange deformation while lowering friction. Dismantling time was reduced from 4 hours per shift to 1.5 hours.

3. Advantages

Wide Service Range

Temperature: -50 °C to +450 °C (up to 550 °C for short-term high-pressure service)

Pressure: ≤2 MPa (low-pressure), ≤10 MPa (high-pressure)

Media: water, steam, oils, mild acids, mild alkalis, and various solvents

Reliable Sealing

Moderate m and y values (minimum design seating stress and gasket factor)

Effective sealing under medium bolt loads

Compression ratio: 15–25%

Resilience: ≥35% (compensates flange unevenness)

Machinability & Cost Efficiency

Shore hardness: 65–85 HS

Easy cutting/punching into complex shapes

Cost: one-third to one-half of graphite composite gaskets

Shelf life ≥3 years

Fire Resistance & Electrical Insulation

Incombustible asbestos fibers (Oxygen Index >50)

Volume resistivity: 10^9 Ω·cm

Applications: fire door cores, high-voltage switchgear insulation pads

4. Limitations & Failure Modes

4. Limitations & Failure Modes

Health & Environmental Risks

The IARC classifies chrysotile asbestos as a Group 1 carcinogen.

Dust concentration ≥0.1 f/cm³ can cause asbestosis and mesothelioma.

Banned in EU and Japan; Chinese standards (GB 5044-2020) mandate enclosed handling and phased substitution.

Permeation & Aging

Rubber matrix undergoes pyrolysis above 300 °C, releasing plasticizers, enlarging pores → “sweating” leakage.

Carbonization in hot oil media causes embrittlement and flange adhesion, complicating maintenance.

Electrochemical Corrosion

Sodium sulfate and chlorides in asbestos absorb moisture, forming electrolytes → galvanic corrosion with carbon steel flanges.

Example: A coastal power plant condenser flange developed 0.5 mm pits in two years, requiring 316L cladding replacement.

Low-Temperature Setback

Below -40 °C, rubber transitions to glassy state; resilience drops to 10%.

Case: A Daqing oil pipeline gasket cracked at -38 °C, necessitating replacement with low-temperature FKM gaskets.

5. Technical Improvements & Alternatives

Metal-Jacketed CAF Gaskets

Stainless steel (0.2 mm) encapsulation reduces fiber exposure and enhances crush resistance.

Used in high-load reactors such as urea synthesis towers (14 MPa, 195 °C).

Eco-Friendly Non-Asbestos Sheets (NAS)

Made of aramid fiber, carbon fiber, and NBR blends.

Replacing CAF in low/medium pressure applications.

Tests: leak rate <1×10^-3 Pa·m³/s at 150 °C, 5 MPa steam—better than equivalent CAF sheets.

Surface Treatments

Graphite/PTFE coatings reduce friction by 30%, prevent flange damage.

Microencapsulated sealants enable crack self-healing, extending service life by >20%.

6. Conclusions & Recommendations

Asbestos rubber sheets remain valuable for thermal power, petrochemical, and metallurgical industries due to their heat, pressure, and chemical resistance combined with low cost. However, regulatory restrictions and health risks confine their use to high-parameter, low-exposure scenarios.

Recommendations:

Prefer certified non-asbestos substitutes for new projects.

For existing CAF installations, establish fiber monitoring, adopt wet processes & negative-pressure dust collection.

In extreme conditions, extend service life via metal encapsulation and surface coatings.

Implement a decommissioning plan aligned with maintenance cycles to ensure safe & compliant transition to eco-friendly gaskets.

Hongwo Sealing Sheet

Hongwo Sealing Sheet

1. Material Overview

1. Material Overview 4. Limitations & Failure Modes

4. Limitations & Failure Modes

Scan the QR Code to start a WhatsApp chat with us.