1. Introduction

1. Introduction

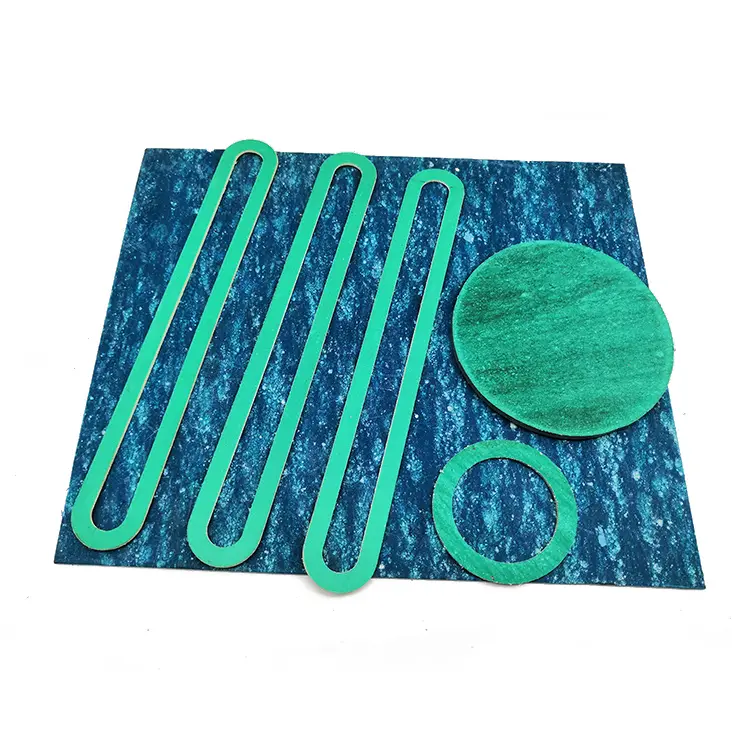

An asbestos gasket sheet is a flexible sealing material. It combines asbestos fibers with an elastomeric matrix and fillers. The mixture is then calendered and pressed to create sheets. These sheets resist high temperatures and pressure. They seal reliably and stay stable in chemicals. This makes them effective barriers against water, steam, and oils. Experts classify asbestos gasket sheets by their temperature and pressure limits. They work well for different tasks. You can use them in low-pressure municipal pipelines or high-pressure chemical process piping. These seals have been a top choice in oil and gas, thermal power, and municipal sectors. Their mature technology and good cost-performance make them favorable. (Reference: GB/T 3985-2018 “Asbestos Gasket Sheet.”)

Note: In the industry, people might call these materials asbestos rubber sheets, paronite gasket materials, or paronite gasket sheets. The names vary by region and specific formulations.

2. Technical data summary

| Key parameter | Unit | Test condition | XB200 (low-pressure) | XB350 (mid-pressure) | XB450 (high-pressure) |

|---|---|---|---|---|---|

| Material composition | — | Component analysis | Asbestos + SBR (styrene-butadiene rubber) | Asbestos + NBR (nitrile rubber) | Asbestos + FKM (fluoroelastomer) |

| Maximum continuous temperature | °C | Air medium, continuous service | ≤200 | ≤350 | ≤450 |

| Maximum working pressure | MPa | 20°C, water medium | ≤1.6 | ≤6.0 | ≤10.0 |

| Permissible leakage rate | Pa·m³/s | 1 MPa, nitrogen medium | ≤1×10⁻⁴ | ≤5×10⁻⁵ | ≤1×10⁻⁵ |

| Tensile strength | MPa | GB/T 528-2009, 50 mm/min | ≥3.0 | ≥4.0 | ≥5.0 |

| Compression set | % | 25 MPa, 30 min dwell | 15–25 | 12–22 | 10–20 |

| Recovery (rebound) | % | After compression test, unload 30 min | ≥35 | ≥40 | ≥45 |

(References: GB/T 3985-2018 “Asbestos Gasket Sheet”; Industrial Sealing Materials Handbook, 2023.)

3. Typical applications

Petrochemical Industry: XB450 is commonly used for high-pressure process piping flanges in catalytic cracker feed lines. This material can handle conditions up to 450°C and 10 MPa. It helps prevent leaks from crude oil and aggressive process streams. (Ref: Sinopec sealing specifications.)

Thermal power plants use XB350 for boiler manhole covers and steam drum interfaces. This material can handle flue gas and steam conditions up to 350°C, ensuring safe operations. (Ref: Thermal Power Sealing Design Guide.)

Municipal water supply and drainage: Low-pressure pipeline flanges, like DN500 water lines, typically use XB200. This material provides reliable and cost-effective sealing under hydrostatic pressures of ≤1.6 MPa. (Ref: Municipal Materials Selection Manual.)

Shipbuilding and marine engineering: Engine-room fuel lines use XB350. This material has an NBR matrix, giving it oil resistance in marine environments. (Ref: Marine Sealing Practice.)

Chemical reactors and vessels: Use XB450 for seals at the lid and shell interface in reactors. This works for organic acids and can handle temperatures up to about 400°C. (Ref: Chemical Equipment Sealing Manual.)

4. Installation and operation best practices

Surface Preparation:

Clean the flange sealing faces of rust and debris.

Aim for surface roughness Ra ≤ 6.3 μm.

Remove local defects to prevent leakage.

(Ref: GB/T 25181-2010.)

Bolt Tightening:

Use the right torque for each grade.

For example, M20 (grade 8.8) should be 35–40 N·m.

Tighten bolts in a diagonal order.

This helps load the gasket evenly.

(Ref: Flange Fastening Technical Procedures.)

Cutting and splicing: Cut gaskets from full sheets. For large splices, overlap by at least 20 mm and seal the joint with approved gasket sealant. The outside diameter of the cut gasket should be 2–3 mm smaller than the flange sealing face diameter. (Ref: Asbestos Gasket Sheet Application Guide.)

Operating limits: Do not exceed the rated temperature or pressure—e.g., do not use XB350 above 350°C or above 6 MPa. (Ref: GB/T 3985-2018.)

Inspection Interval: For high-temperature and high-pressure services, inspect seals every three months. Replace gaskets if you see any signs of aging or cracking.

(Ref: Industrial Equipment Maintenance Manual.)

5. Frequently asked questions

Q: Can asbestos gasket sheets be used to seal concentrated hydrochloric acid?

A: No. Conventional elastomer matrices have limited resistance to strong acids. Use an FKM XB450-FF variant or choose a non-asbestos option that has verified chemical compatibility. (Ref: Sealing Materials Corrosion Guide.)

Q: Can different pressure-grade gaskets be mixed?

A: Not recommended. Low-grade materials can’t handle mid- or high-pressure conditions well. While you can use a high-grade gasket in a low-pressure setting, it’s not cost-effective. Select according to operating conditions and standards (GB/T 3985-2018).

Q: If slight leakage occurs, may bolt torque be increased?

A: If leakage happens from low bolt preload, retighten to no more than 10% above the nominal torque. If leakage keeps happening due to damaged seals or the wrong gasket, take it apart and replace it. Too much compression can harm the gasket. (Ref: Pressure Equipment Sealing Fault Guide.)

Q: What indicators need immediate gasket replacement?

A: Look for surface cracks, embrittlement (rebound < 30%), visible leaks, and thickness loss of over 15%. Also, check for ongoing leaks after tightening. (Ref: Sealing Maintenance & Replacement Standard.)

Q: Are asbestos gaskets permitted in environmentally regulated areas?

A: Increasingly restricted. In areas with strict asbestos rules, use non-asbestos gaskets, like aramid-fiber-based ones. These can perform like XB350 up to about 300°C. Also, check that they work well with the process media. (Ref: Eco-friendly Sealing Material Standards.)

6. Conclusions and engineering recommendations

6. Conclusions and engineering recommendations

Conclusions: The asbestos gasket sheet is key for industrial static sealing. It offers great temperature and pressure resistance, reliable sealing, and is cost-effective. Choosing the right material grade is important. Also, follow standard installation practices. Lastly, observe environmental rules. These steps ensure safe and long-lasting operation. (Synthesis of GB/T 3985-2018 and sector practice.)

Recommendations for engineers

Use a “media – temperature – pressure” selection matrix. For example:

Fuel lines → XB350 (NBR)

High-temperature flue/steam → XB450 (FKM)

Avoid single-parameter selection.

Check flange flatness before installing. It should not deviate more than 0.1 mm/m. Also, use a calibrated torque wrench to avoid assembly errors.

Install a usage register.

Replace XB450 gaskets every 12 months for continuous high T/P service.

Replace XB200 gaskets every 24 months for low-pressure service.

Maintain a stock of non-asbestos alternatives to follow evolving environmental requirements.

Hongwo Sealing Sheet

Hongwo Sealing Sheet

1. Introduction

1. Introduction 6. Conclusions and engineering recommendations

6. Conclusions and engineering recommendations

Scan the QR Code to start a WhatsApp chat with us.