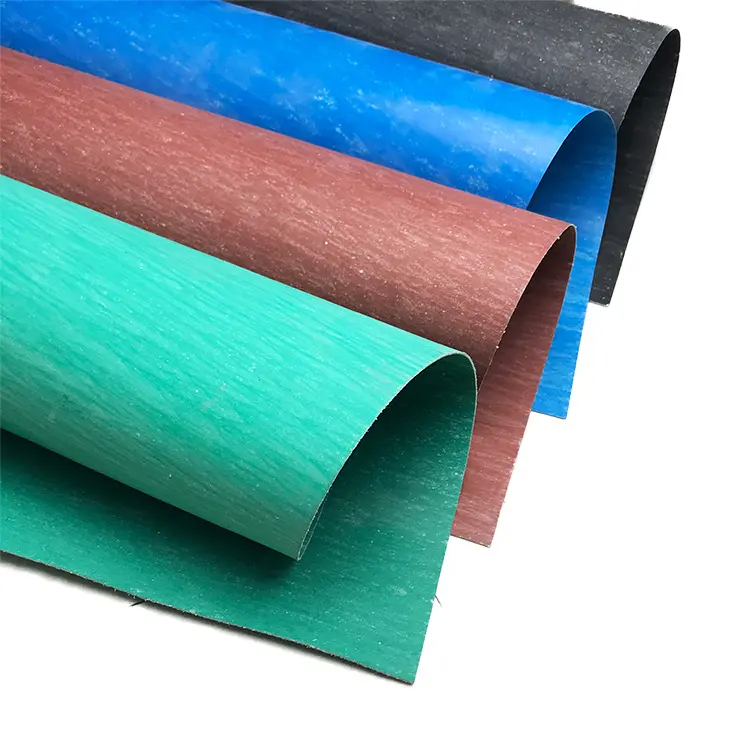

Non Asbestos Sheet Temperature Range Non Asbestos Sheet Standard (also known as non-asbestos gasket sheet, asbestos-free sealing sheet, or non-asbestos sealing material.)

Summary

Summary

The temperature range for usable non-asbestos sheets varies. It depends on the fiber substrate and the elastomeric binder.

We group non-asbestos sheets into three temperature-grade families. They can handle continuous service from –200 °C to +450 °C. The types are:

Ambient (room temperature) type

Mid-temperature type

High-temperature type

Select temperature, media, and flange pressure together. Long-term overheating hardens and cracks the elastomer. This leads to a big increase in leakage rates. Standards testing, like EN 13555 for creep relaxation and sealing re-verification, is important. It helps ensure lifecycle reliability and compliance.

1. Ambient/general-purpose type

Binder: styrene-butadiene rubber (SBR) or similar.

Reinforcement: aramid (aramid/aramid fiber) reinforcement.

Temperature limits: long-term continuous use up to 180 °C, short-term peak up to 210 °C.

Typical use:

Cooling water systems

Gearboxes

General sealing tasks where normal temperature resistance is enough.

2. Mid-temperature type

Binder: nitrile rubber (NBR).

Reinforcement: aramid or glass fiber.

Temperature limits: continuous use up to 250 °C; in steam environments, downgrade one class to 200 °C.

Mechanical targets: compression (design) around 12% ± 5%, recovery (rebound) ≥ 45%.

Typical use: gasoline/diesel engines, heat exchangers, chemical pumps, and valves.

3. High-temperature type

Additives/construction: graphite, mica, or metal skeleton inserts to raise thermal limits.

Temperature Limits:

Continuous resistance: up to 400 °C

Instantaneous peaks: up to 450 °C

Maintain sealing contact pressure: ≥ 8 MPa

Typical uses include:

Flue gas desulfurization

Heavy-oil burners

Turbocharger piping

Other smoke and combustion applications.

Design & selection guidance

Always check the temperature, fluid/chemical compatibility, and flange pressure together.

Long-term heat can make elastomers brittle and lead to microcracks. Keep the continuous operating temperature below 80% of the material’s peak short-term temperature.

Perform creep-relaxation and leakage re-tests. Follow EN 13555 or similar standards after you select the design. This checks the sealing performance for its expected lifespan.

Supplier & material assurance (manufacturer example)

Hengshui Aohong with 15 years of focus on non-asbestos sealing materials, offers a full range of sheets. These sheets provide continuous service from –50 °C to +400 °C and are available in bulk. Standard offerings: thickness 0.5–5.0 mm, cut to width within 1,500 mm. Certifications and compliance: ISO 9001, RoHS, REACH; compression-rebound performance meets GB/T 12621-2008. Stock items ship the same day; custom orders ship in three days. Material reports and third-party test certificates are available on request.

Practical notes for engineers.

Use conservative design margins for temperature and pressure. This is important when the flange class or media chemistry is unclear.

Request supplier material data sheets and third-party test reports before final selection.

For critical services, use EN 13555 type testing. Also, verify leakage and creep as the client specifies. This testing should happen under typical temperature and pressure cycles.

Conclusion

To prevent elastomer damage and leaks, know the temperature range for non-asbestos sheets. Also, using the right non-asbestos sheet standard is key for long service life. Using the right binder and fiber reinforcement is key. Materials like graphite, mica, or metal inserts work well for high heat. This setup will ensure reliable sealing. This works well for both low-temperature cryogenic conditions and high-temperature combustion applications.

Hongwo Sealing Sheet

Hongwo Sealing Sheet

Summary

Summary

Scan the QR Code to start a WhatsApp chat with us.