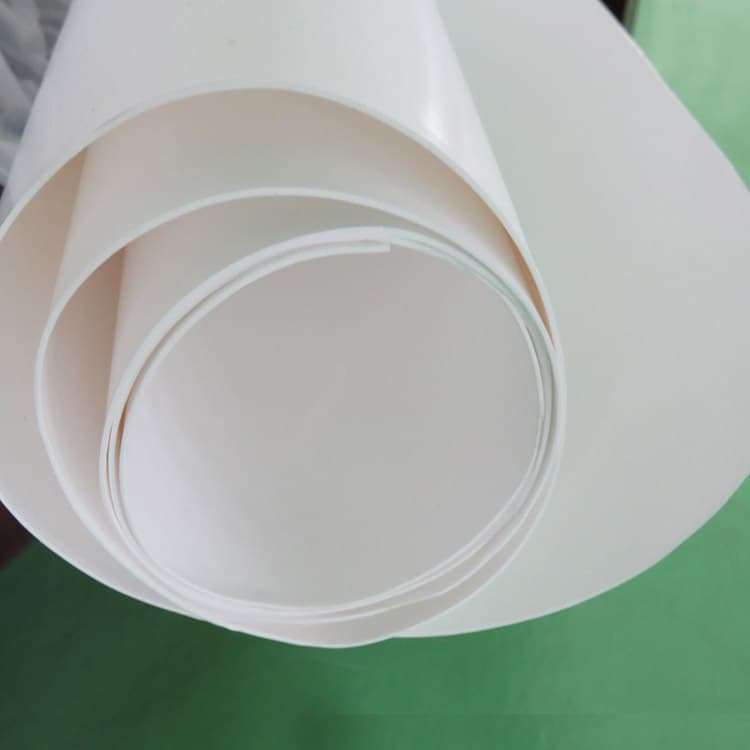

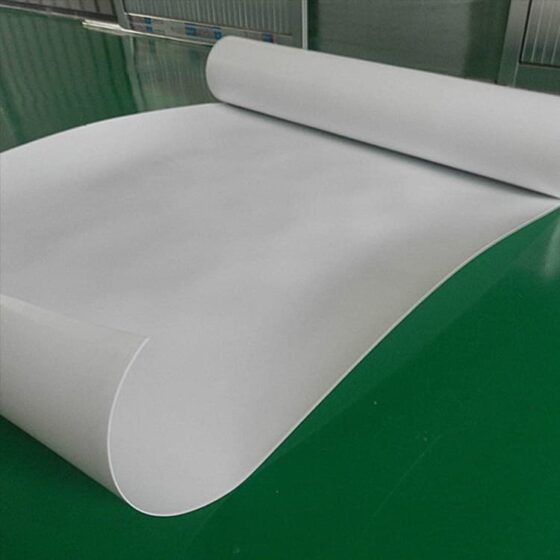

High Temperature Resistant Anti-static PTFE Elastic Sheet

Product Introduction

Hongwo’s High Temperature Resistant Anti-static PTFE Elastic Sheet is an advanced engineered material designed for extreme environments requiring superior thermal stability, static dissipation, and flexibility. Combining PTFE’s inherent chemical resistance with enhanced elasticity and anti-static properties, this sheet is ideal for industries where contamination control, durability, and electrical safety are critical.

Key Applications

✅ Semiconductor & Electronics – Protects sensitive components from static discharge while withstanding high-temperature processes.

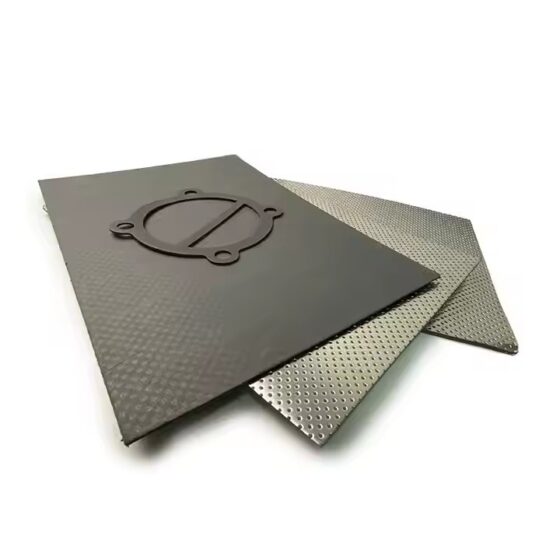

✅ Aerospace & Defense – Used in gaskets, seals, and insulation for engines and avionics.

✅ Chemical Processing – Resists aggressive chemicals and prevents static buildup in explosive environments.

✅ Medical & Pharma – Biocompatible, anti-static surface for cleanroom equipment and sterile packaging.

✅ Automotive – High-temperature seals and gaskets for fuel systems and electric vehicle (EV) components.

Detailed Product Parameters

| Property | Value | Unit |

|---|---|---|

| Material Type | Carbon/Graphene-Filled PTFE | – |

| Thickness | 0.2 – 10 | mm |

| Surface Resistivity | 10⁶ – 10⁹ | Ω/sq |

| Tensile Strength | 10 – 30 | MPa |

| Elongation at Break | 250% – 400% | % |

| Temperature Range | -200°C to +280°C | °C |

| Coefficient of Friction | 0.08 – 0.15 | – |

| Compression Set | ≤20% (after 24h @ 25°C) | % |

Technical Advantages

🔹 Static Dissipation – Carbon/graphene additives ensure controlled surface resistivity (10⁶–10⁹ Ω/sq), preventing ESD damage.

🔹 Elastic Recovery – Maintains seal integrity under compression, even after repeated thermal cycling.

🔹 Extreme Temperature Resistance – Performs reliably from cryogenic to +280°C.

🔹 Low Outgassing – Meets NASA/ESA standards for vacuum applications.

🔹 Easy Maintenance – Non-stick surface reduces contamination and cleaning costs.

Brand Style – Hongwo

🏭 Precision Engineering – Rigorous quality control ensures consistent anti-static performance.

🌍 Certified Excellence – Complies with ISO 9001, ASTM D1711 (ESD), and FDA standards.

💡 Custom Solutions – Tailored formulations for specific resistivity, thickness, or filler requirements.

Lifespan & Cost Efficiency

⏳ Service Life – 8–12 years in static applications; 5–7 years under dynamic stress.

💰 Low TCO – Outperforms silicone/rubber alternatives in high-temperature environments, reducing downtime.

(Custom sizes, colors, and resistivity levels available – Contact Hongwo for OEM/ODM projects.)

Why Choose Hongwo?

✔ 20+ Years of PTFE innovation

✔ 24/7 Technical Support for application optimization

✔ Fast Lead Times – Samples ready in 3–5 working days

(Note: Performance data based on lab tests; actual results may vary by use case.)

Hongwo Sealing Sheet

Hongwo Sealing Sheet

Scan the QR Code to start a WhatsApp chat with us.