Product Description

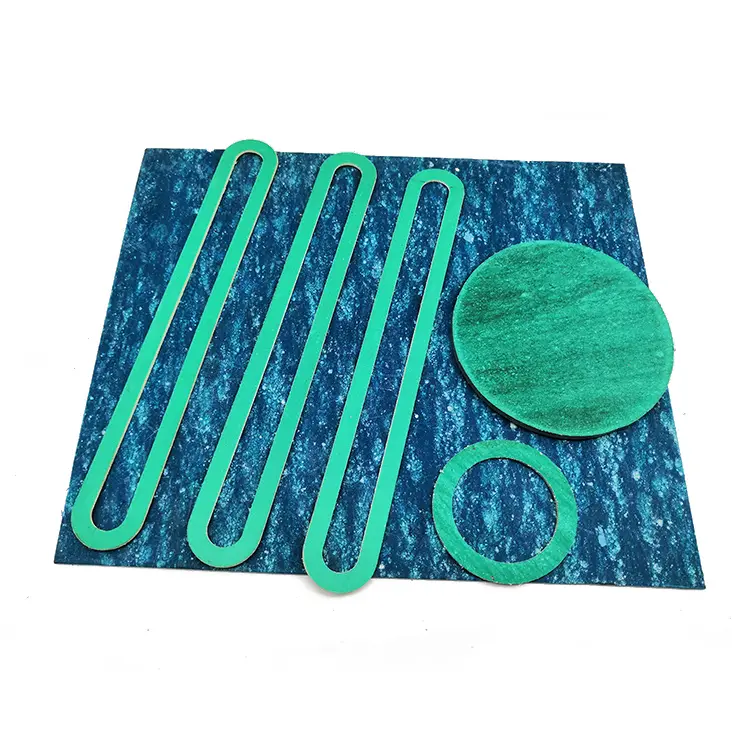

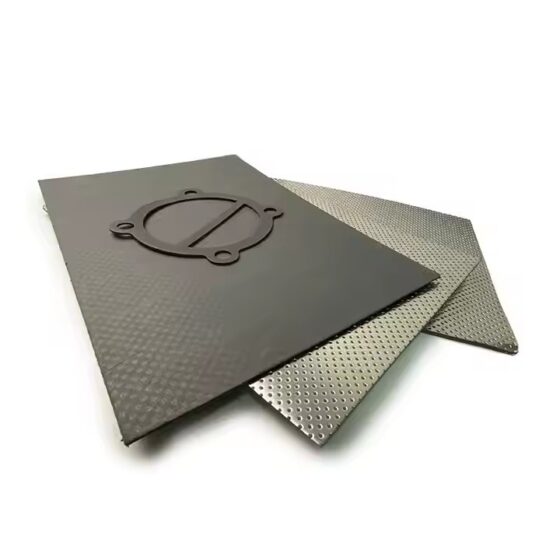

Non-Asbestos Gasket Sheets are manufactured using aramid fiber, inorganic fillers, and high-quality rubber binders. They deliver outstanding sealing properties without the health risks associated with asbestos. These sheets are widely used for flange connections, pump housings, and machinery joints in industries such as petrochemical, power generation, shipbuilding, and automotive manufacturing.

Technical Specifications

Technical Specifications

Working Pressure: 4.0 MPa

Working Temperature: 350℃

Standard Sizes:

4600 × 1500 × (0.3 – 6.0) mm

4100 × 1500 × (0.3 – 6.0) mm

3810 × 1270 × (0.3 – 6.0) mm

3800 × 2700 × (0.3 – 6.0) mm

2000 × 1500 × (0.3 – 6.0) mm

1500 × 1360 × (0.3 – 6.0) mm

1270 × 1270 × (0.3 – 6.0) mm

1500 × 1500 × (0.3 – 6.0) mm

Other sizes can be customized upon request.

Packaging: Rolls and Wooden Pallets

Grades (according to temperature & pressure):

NXB150#, NXB200#, NXB250#, NXB300#, NXB350#

Alternative Names: Non-Asbestos Sheet, Asbestos-Free Rubber Sheet, Aramid Fiber Sheet

Production Standard: GB/T 22209-2021

Physical Properties of Non-Asbestos Rubber Sheet

| Item | Unit | NXB150 | NXB250 | NXB350 |

|---|---|---|---|---|

| Density | g/cm³ | 1.8 ± 0.2 | 1.8 ± 0.2 | 1.8 ± 0.2 |

| Transverse Tensile Strength | MPa ≥ | 7.0 | 9.0 | 12.0 |

| Compressibility | % | 30 ± 5 | 12 ± 5 | 12 ± 5 |

| Recovery | % ≥ | 50 | 40 | 45 |

| Creep Relaxation | % ≤ | 50 | 45 | 45 |

| Flexibility | – | No Cracks | No Cracks | No Cracks |

| Fluid Resistance | – | – | – | – |

| Thickness Increase after Immersion in ASTM IRM903 Oil (150℃ ± 1℃, 5h) | % | 0–5 | 0–25 | 0–25 |

| Weight Increase after Immersion in ASTM Fuel Oil B (20–30℃, 5h) | % | 0–25 | 0–20 | 0–20 |

| Thickness Increase after Immersion in Water (100℃ ± 2℃, 5h) | % | 0–20 | 0–15 | 0–15 |

| Gas Tightness (N₂ pressure: 1.0 MPa, gasket load: 35.0 MPa) | ml/min ≤ | 0.01 | 0.05 | 0.05 |

| Gas Permeability (N₂ pressure: 4.0 MPa, gasket load: 32.0 MPa) | ml/min ≤ | 0.2 | 1.0 | 1.0 |

Key Applications

Petrochemical Industry: Flange sealing under high pressure and temperature

Power Plants: Boiler and turbine sealing

Automotive Sector: Engine gasket sheets, exhaust systems

Marine Industry: Pump housings, valve sealing

General Machinery: Industrial pipeline sealing, compressors

Advantages of Non-Asbestos Gasket Sheets

✅ Asbestos-Free & Eco-Friendly – Safe for workers and compliant with global regulations

✅ High Temperature Resistance – Stable sealing up to 400°C

✅ Excellent Chemical Resistance – Resistant to oils, fuels, and solvents

✅ Durable & Long Service Life – Withstands high pressure and frequent operation

✅ Custom Sizes & OEM Service – Available in sheets, rolls, or cut gaskets

FAQ – Frequently Asked Questions

Q1: Do you offer discounts for bulk orders?

Yes. We provide competitive wholesale pricing and flexible discounts for large-volume purchases.

Q2: Can I get a sample before placing a bulk order?

Of course. Free samples are available; customers only need to cover courier costs.

Q3: What are your payment terms?

We accept T/T, L/C, and Western Union. For long-term clients, flexible payment terms can be discussed.

Q4: What are your delivery terms?

We support FOB, CIF, CFR, and EXW according to customer requirements.

Q5: How long is the delivery lead time?

Normally 7–15 working days depending on order quantity and customization.

Hongwo Sealing Sheet

Hongwo Sealing Sheet

Technical Specifications

Technical Specifications

Scan the QR Code to start a WhatsApp chat with us.