1. Introduction

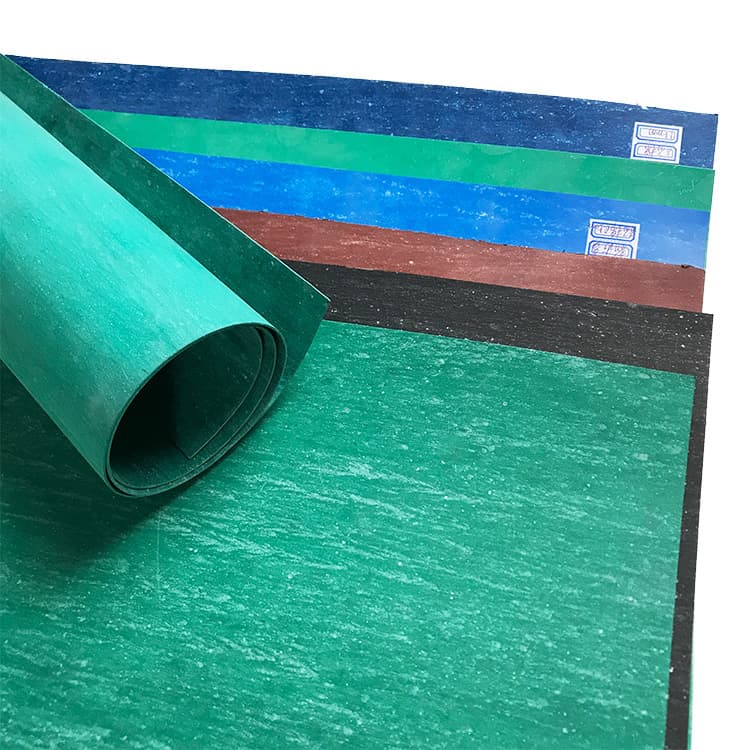

In harsh operating conditions where high temperature, high pressure, and chemical corrosion coexist, sealing failure is often the primary cause of unplanned shutdowns. High Temperature Resistance Asbestos Rubber Sheet, also referred to as Compressed Asbestos Fiber (CAF) Rubber Sheet, combines the heat-resistant framework of asbestos fibers with the elasticity of a rubber matrix. Even above 400 °C, it maintains acceptable sealing stress, making it an irreplaceable “last millimeters” barrier in thermal power, petrochemical, and metallurgical industries.

This article analyzes six typical engineering cases from the past five years and explains the functional mechanisms, performance boundaries, and failure modes of asbestos rubber sheets in high-temperature sealing. Strategies for extending service life and transitioning to alternatives are also discussed.

2. Micro–Macro Synergistic Heat Resistance Mechanism

Three-Dimensional Asbestos Fiber Network

Chrysotile asbestos begins dehydroxylation at ~550 °C. Below 450 °C, it retains >80% of its original tensile strength, forming the thermal skeleton.Rubber Vulcanization Cross-Linking

NBR/EPDM blends begin chain scission above 250 °C. With ZnO/MgO curing and antioxidant DSTDP, thermal-oxidative aging induction time extends to 3000 h (ASTM D573, 300 °C).Interface Thermal Resistance

Rubber-asbestos interfacial resistance (0.03 m²·K/W) is much lower than pure rubber (0.12 m²·K/W), promoting axial heat conduction along fibers and suppressing local degradation.Compression Recovery

At 300 °C and 30 MPa, XB450-type asbestos rubber sheet achieves 18% compression and >45% recovery, ensuring flange interface compensation after bolt unloading.

3. Engineering Case Studies

3. Engineering Case Studies

Case 1: Huaneng Qinbei Power Plant – 1000 MW USC Steam Pipeline (28 MPa / 610 °C)

Issue: Graphite spiral wound gaskets cracked during thermal shocks.

Solution: 3 mm XB450 asbestos rubber sheet + 0.2 mm graphite coating. Bolt torque reduced from 680 N·m to 520 N·m.

Result: 18,000 h continuous operation, helium leak rate <1×10⁻⁶ Pa·m³/s, only 7% permanent set after 200 start-stop cycles.

Case 2: Sinopec Maoming – E-201 Heat Exchanger Manhole (3.2 MPa / 450 °C oil-gas)

Issue: PTFE gasket lacked rebound, required 6-month overhauls.

Solution: Oil-resistant CAF (NBR base), 2 mm, reinforced with 316L serrated metal ring.

Result: Overhaul interval extended to 24 months, saving RMB 350,000 per cycle.

Case 3: Baosteel No.4 Blast Furnace Hot Blast Pipe (0.45 MPa / 220 °C, thermal shock ±150 °C)

Solution: XB350 asbestos rubber sheet, 4 mm + graphite coating.

Result: 5000 cycles without delamination, bolt load loss <10%.

Case 4: Xinjiang Chlor-Alkali Plant – Wet Chlorine Pipeline (0.6 MPa / ambient, chlorine water + HCl mist)

Solution: Blue asbestos + FKM composite CAF, 1.5 mm.

Result: No embrittlement after 5 years, flange intact; 2.5× longer service than EPDM gasket.

Case 5: CNOOC Huizhou Refining – Delayed Coker Bottom Cover (4.0 MPa / 480 °C, sulfur-containing oil)

Solution: CAF encapsulated with Inconel 600 lip ring (semi-metal gasket).

Result: After 8000 h, thickness reduction only 0.12 mm; repair downtime reduced from 72 h to 12 h.

Case 6: Baowu Converter – Steam-Cooled Duct (1.2 MPa / 380 °C intermittent steam)

Solution: XB350 asbestos rubber sheet, 5 mm, ceramic-modified silicone resin coating.

Result: 8000 cycles without cracks; annual steam savings equal to 120 t standard coal.

4. Performance Limits and Failure Modes

Temperature Limit: Long-term CAF use up to 450 °C; beyond 500 °C rubber carbonizes, fibers powder, leakage rises exponentially.

Pressure Limit: At 550 °C, m factor rises from 2.75 to 4.2, requiring >50% higher bolt loads, impractical in engineering.

Chemical Aging: Sulfur-rich oils cross-link with rubber double bonds, increasing Shore A hardness from 75 to 92, reducing resilience to 15%, leading to brittle fracture.

Fiber Migration: Under vibration, asbestos fibers migrate to bolt holes, forming weak zones and localized leakage.

Health Risk: At >300 °C, rubber volatiles may carry fibers; emission up to 0.05 f/cm³, close to GBZ 2.1-2019 exposure limits.

5. Service Life Extension & Risk Control

Composite Structures: Stainless steel foil (0.1 mm) encapsulation reduces fiber release by 90% and improves blow-out resistance.

Coating Technology: Graphite-phosphate coatings form a glassy protective film at 550 °C, suppressing oxidative mass loss.

Bolt Thermal Compensation: Inconel 718 high-temperature bolts with matching thermal expansion reduce relaxation.

Online Monitoring: Acoustic emission sensors provide 30-minute leakage pre-warning.

Replacement Routes:

<350 °C, <6 MPa: Aramid/NBR non-asbestos sheets.

450 °C: Flexible graphite + spiral wound or nickel-alloy toothed gaskets.

Transitional: CAF + metal ring semi-metal gaskets for gradual phase-out.

6. Conclusion

High Temperature Resistance Asbestos Rubber Sheet continues to offer unique techno-economic advantages in high-temperature sealing, especially under conditions of 350–450 °C, 3–10 MPa, with oil, mild acids, and alkalis. Its combined compression resilience and thermal resistance remain unmatched by a single substitute material.

Through composite design, surface coatings, and online monitoring, service life can be extended by 30–50% while reducing fiber exposure risk. With stricter regulations and material innovation, CAF will gradually give way to non-asbestos and metal composite gaskets. However, during the transitional stage, asbestos rubber sheets remain a critical sealing element for ensuring long-term industrial safety.

Hongwo Sealing Sheet

Hongwo Sealing Sheet

3. Engineering Case Studies

3. Engineering Case Studies

Scan the QR Code to start a WhatsApp chat with us.